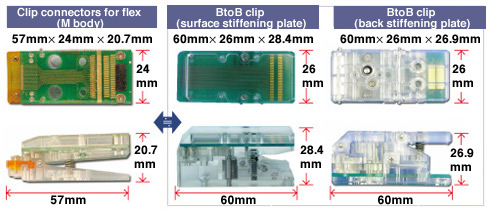

BtoB Clip is durable and can significantly reduce the total cost of jig maintenance by using a high quality probe without using the connector on the other side.

If you use Other side connector

- Poor workability because visibility is bad

- There can damage the inspection side

- of the connector when removing

- the inspection after the connector.

- Low durability

When we use our product

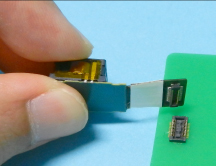

- Improved visibility is good workability

- Just easily bite as a clothespin!

- Since the lock mechanism

- is not there is no worry damage to

- the inspection side of the connector.

- High durability (200,000 tests clear)

Recommended for use in the following cases

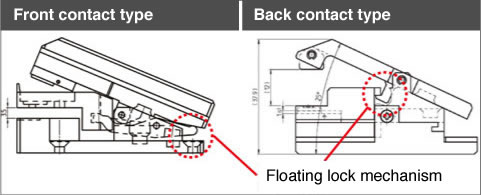

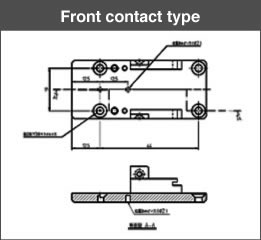

Surface stiffening plate (top contact)

the inspection item and the connector are mounted on the same plane (requires a connection to an extremely low-profiled connector)

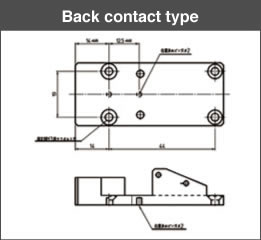

Back stiffening plate (bottom contact)

The inspection item and the connector are mounted on opposite planes (the inspection item and the connector are located in close proximity)

Features

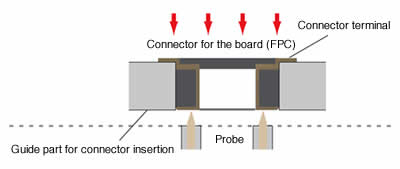

- Connector mounting displacement absorption structure

Due to a structure that guides the connector external form as it is inserted, inspections are unaffected by mounting displacement between the connector and board (FPC). - Wide space for inspection item placement

The wide area allocated for mounting of the board (FPC) makes placing the inspection item easy. - Wide opening area

The opening part is expanded to improve working efficiency. - Probe protection structure

Surface stiffening plate: The guide shape is configured to prevent incorrect insertion of the inspection item. - Back stiffening plate

Since the guide tends to float, a structure has been adopted that prevents a probe from directly touching the connector when the inspection item is placed into position. - Floating lock mechanism

The guide part (floating guide) is configured so that it does not descend when the inspection item is placed into position. (Applies only at full-open time.)

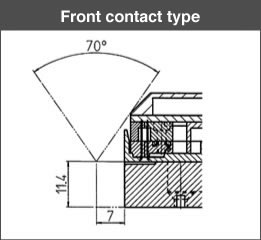

- Superior visibility

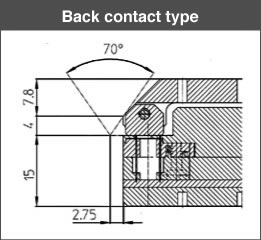

Height has been minimized, and the top front-end part is cut to improve visibility of the inspection item. By accounting for inspections by camera modules, we have devised a way to avoid affecting the angle of view.

*Angles of view up to 70° are supported even when the center of lens is close to a position 2.75 mm from the BtoB clip end face.

- Probes can be swapped while leaving the base intact

- Since the structure accommodates probes, when the base part is attached to an inspection device, the probe can be exchanged. This eliminates position adjustments at each probe replacement.

- Positioning pins installable

- A 2-mm diameter hole is provided for positioning pins opened to allow precise placement at a desired position.

Probe contact position

Depending on the solidity of the solder applied, a probe with mild spring pressure is moved against the top of the connector terminal, rather than an instable connector lead.

Wiring type

for discrete wiring

pad-fitted type

Relationship between Pin Numbers and Fitted FRC connectors

| Target pin number | Connectors used |

|---|---|

| 10 to 32 pins | HIF6-32PA-1.27DS |

| 34 to 40 pins | HIF6-40PA-1.27DS |

| 42 to 60 pins | HIF6-60PA-1.27DS |

General Specification

| Maximum rated power | MAX.10W |

| Maximum rated current | 0.5A |

| Maximum rated voltage | 50V(AC/DC) |

| Withstand voltage | AC100V/1min |

| Insulation resistance | MIN100MΩ |

| Contact resistance | MAX.500mΩ(contact part) |

| Working temperature range | 0~85℃ |